Why hot runner for die-casting?

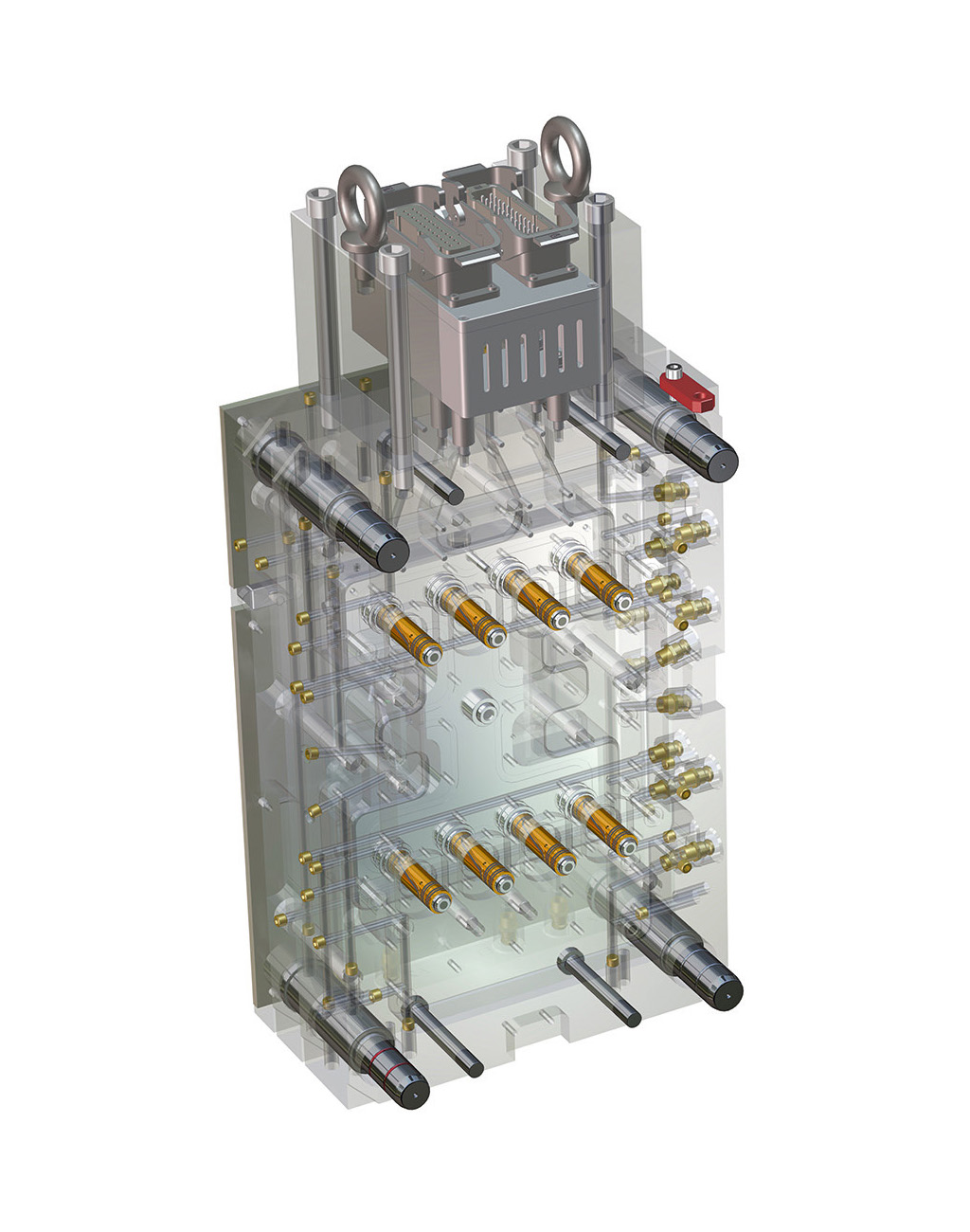

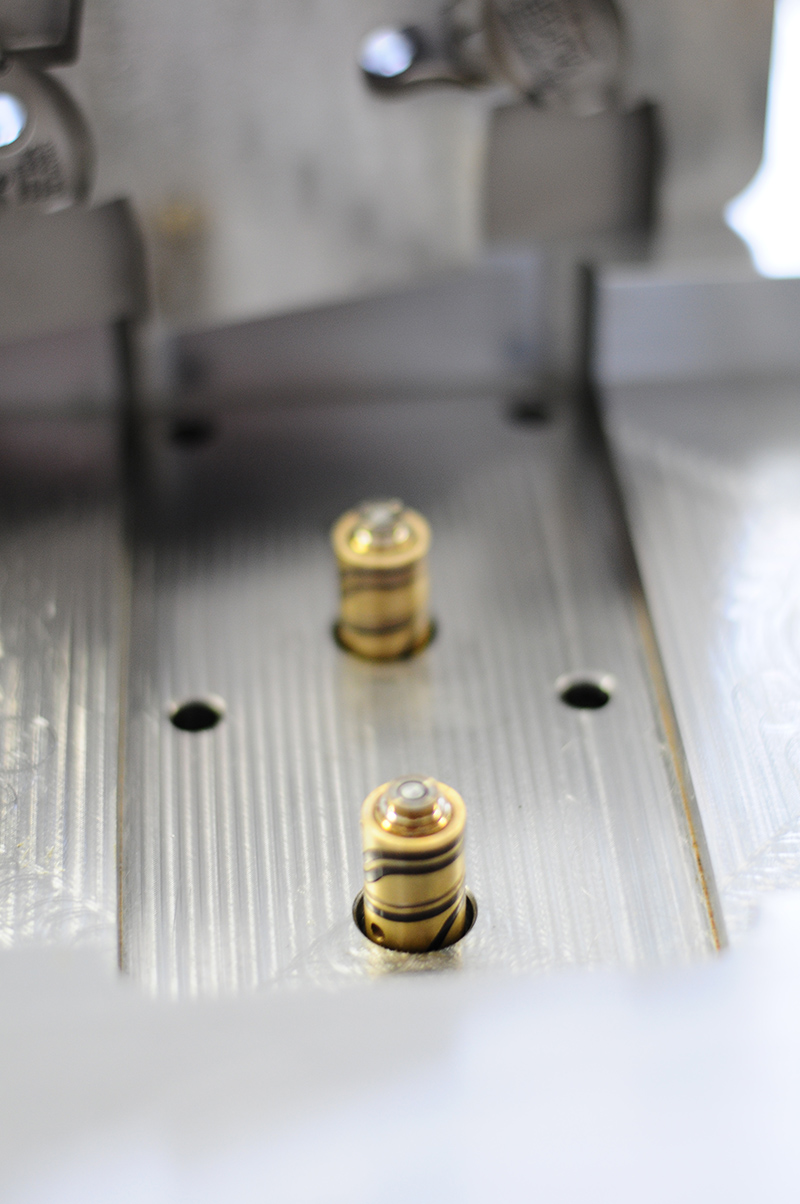

As a result of the development of this process, as well as its conversion into a die-casting hot runner, a sprueless production is made possible for the first time.

Learn more

Production without secondary processing

Direct gating of the parts allows rework-less production analogue to today's production of plastic parts.

Advantages for manufacturing

checkThe cycle time is significantly reduced!

checkProduction amount rate is increased

checkSecondary processing steps are not necessary

checkEnergy efficiency is increased

checkReturn materials are eliminated / massively reduced

Sprue-system is completely eliminated

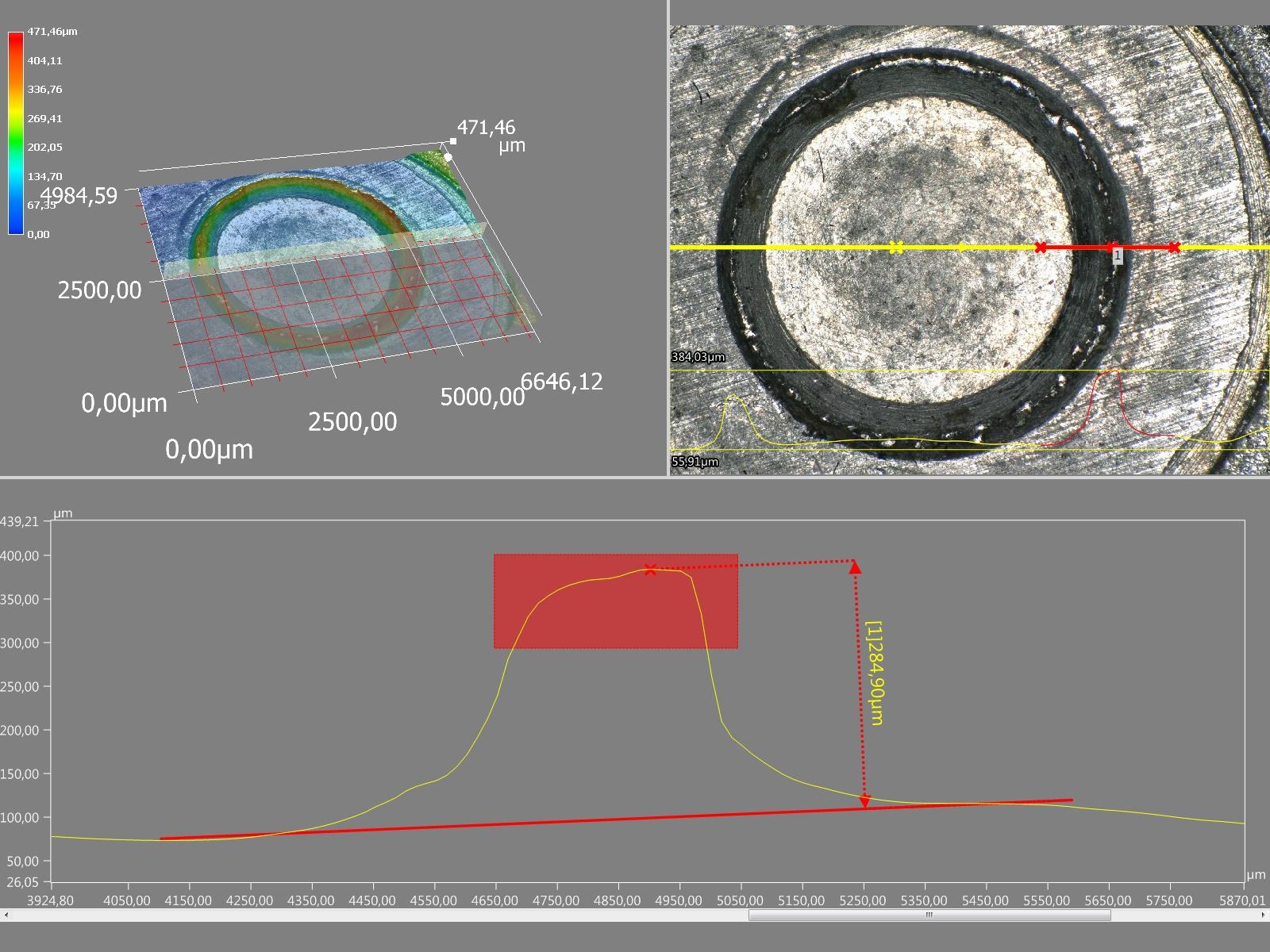

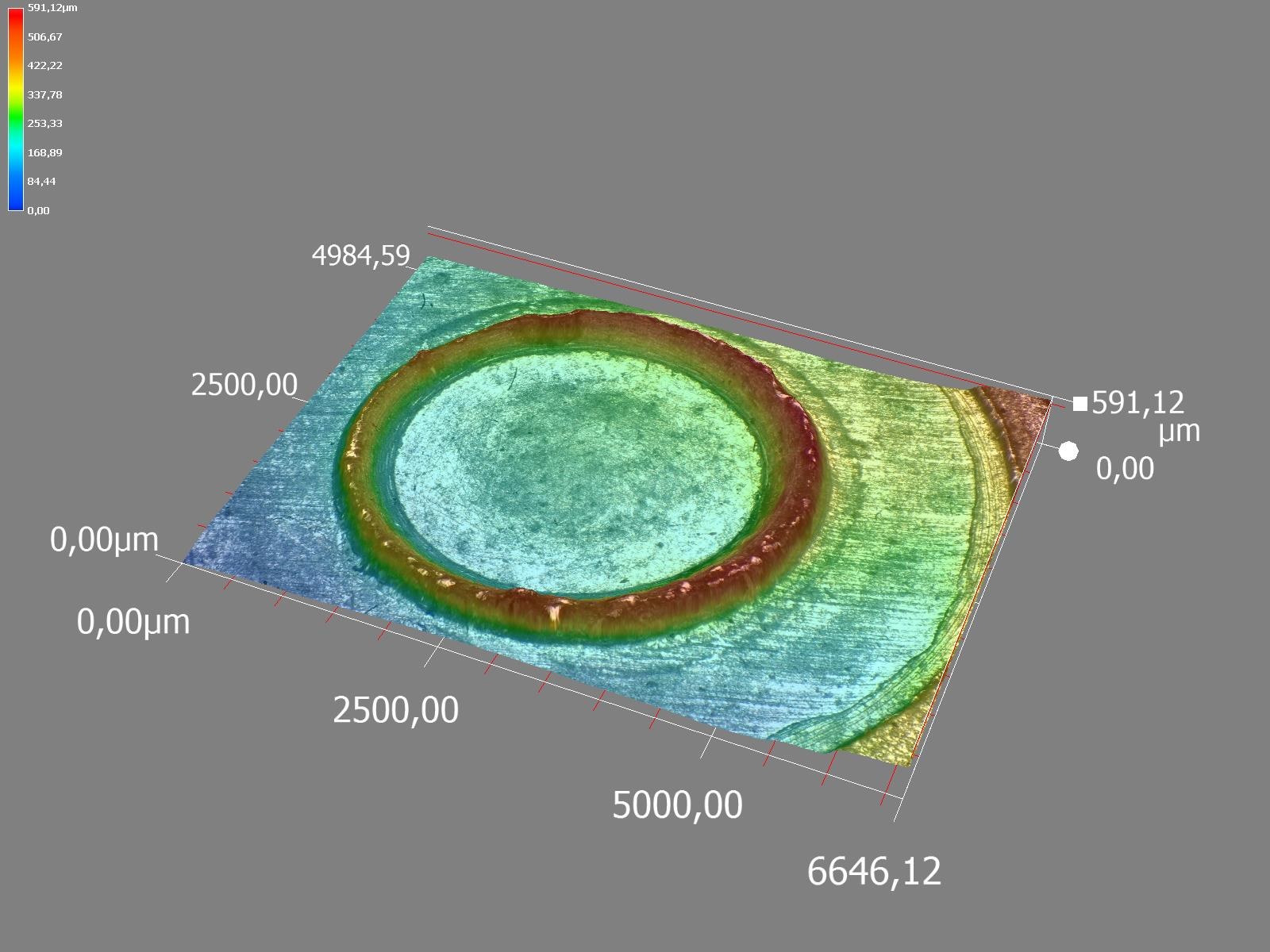

Wear in the sprue area (article gate) has led to

the considerable reduction in the mould durability.

Avoid wear

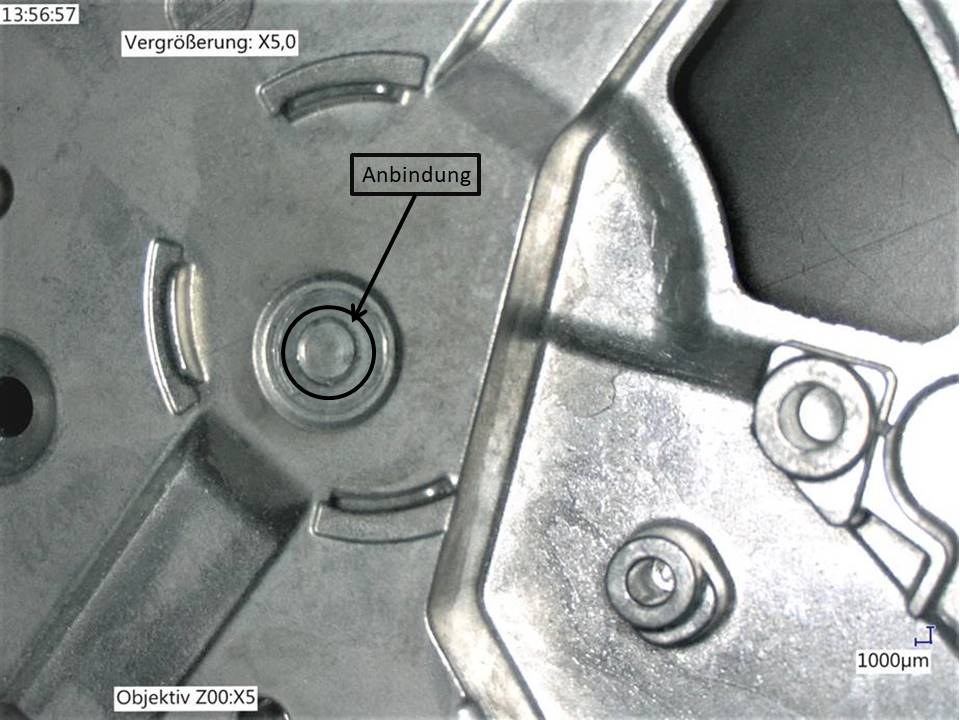

Due to the direct gating to the article and the use of wear-resistant materials, the wear in the sprue area is eliminated.

Elimination of overflow chambers

Overflow chambers will be omitted for most parts.

Conventional casting: Energy consumption

The amount of material to be melted and reintroduced into the process (sprues / return material) is currently about 40% of the annual production of die-cast zinc!

Conventional casting: Article quality

Until now, the complete sprue system had to be evacuated, which is often a multiple of the article volume. This has so far happened over the overflow chambers, as well as the mold separation. Regardless of the caused by reaction, the porosity of the articles is increased.

Hot runner casting:

By using the hot runner, the melt is fed directly to the article under appropriate pressure. As a result, there is hardly any oxide foam and the proportion of air to be evacuated is massively reduced. This also reduces the porosity of the articles.